What are raw materials for pet blow moulding machine production?

When this question is asked, you will think about cost, security and functionality of pet blow moulding machine. A manufacturer is expected to ascertain the source of raw material, reduce the price for raw material and use innovative technologies, so as to enhance the performance-cost ratio. Today the majority of the manufacturers would examine their raw materials before processing. They might even encourage third parties to check the materials and issue test reports. Strong partnerships with raw material suppliers are of great importance to the pet blow moulding machine manufacturers. Because this means that their raw materials would be guaranteed by cost, quality and quantity.

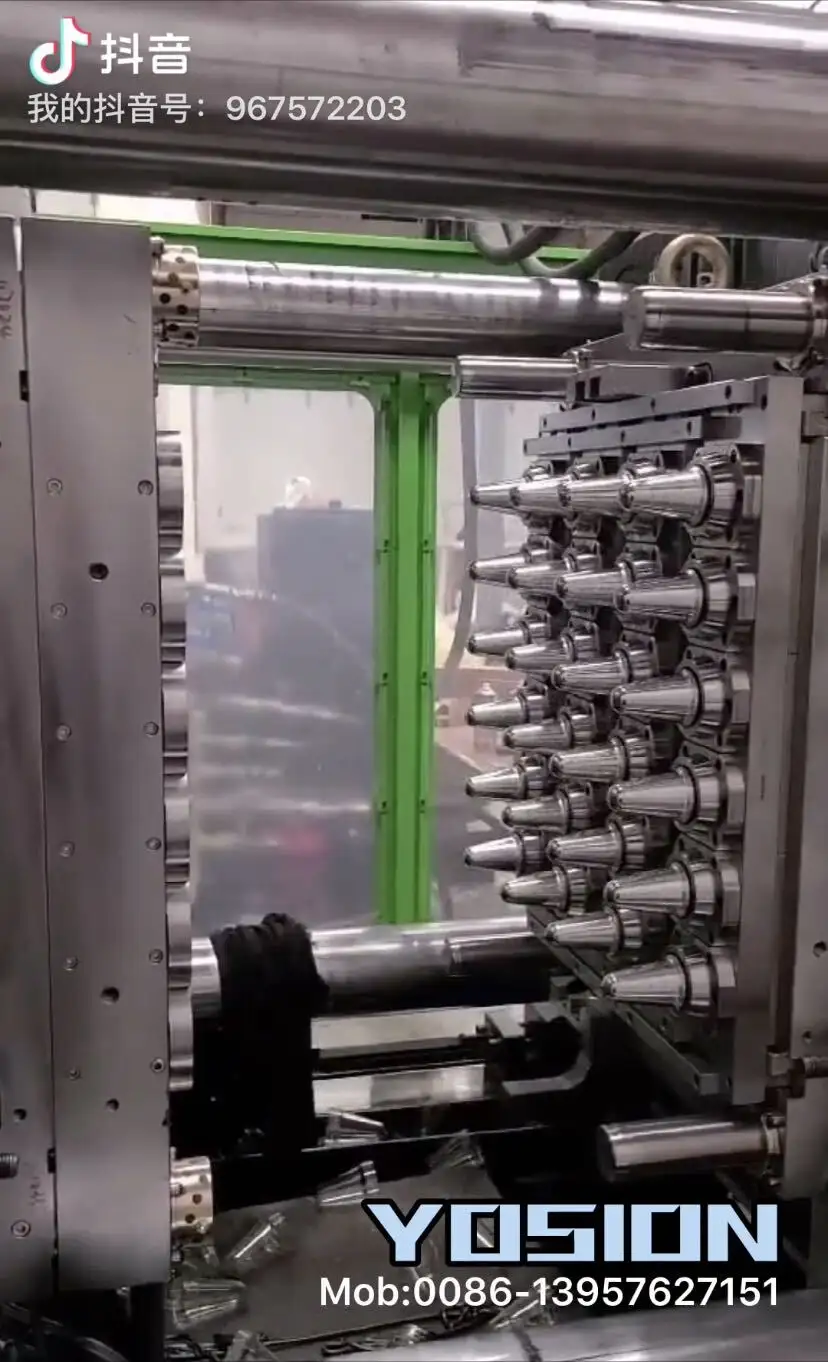

Yosion Machinery mainly manufactures and supplies excellent pet injection machine. According to the material, Yosion Machinery's products are divided into several categories, and pet injection machine is one of them. The product has excellent and flexible temperature adaptability. It is sintered under high temperature which is up to more than 2500 degrees Fahrenheit. It is distinguished by its high speed and low compressed air consumption. Yosion Machinery's reliable service and dedicated staff have always been valued by customers around the world. The compact preform-chain pitch design ensures efficient heating and helps reduce energy consumption.

Our mission is to provide the best product solutions by exceeding customer's expectations on product and service. We will take the clients' requirements seriously.