How much will it cost for pet blow moulding machine production?

Production cost is the combined total cost of raw material and direct labor costs and burden incurred in production. As the resources used to manufacture the pet blow moulding machine, the production cost involves several elements including the purchase of raw machinery, wages of labor, interest on capital, and insurance charges. The cost of the production is categorized into two parts: fixed cost and variable cost. At present, most manufacturers in the market reduce the manufacturing cost for obtaining increased profits by strictly controlling the variable cost.

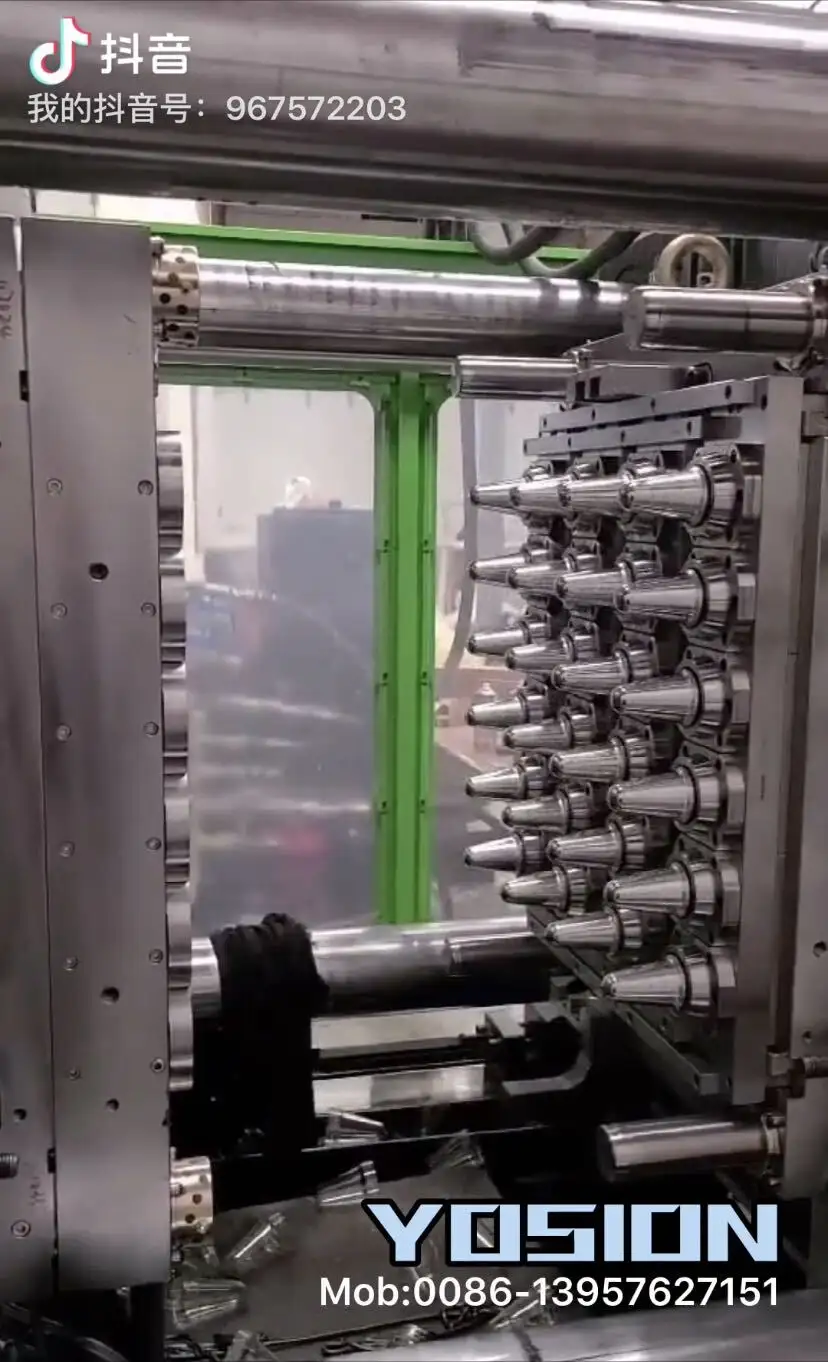

Yosion Machinery is a leading pet injection machine supplier which is dedicated to manufacturing. According to the material, Yosion Machinery's products are divided into several categories, and plastic bottle making machine is one of them. Yosion Machinery plastic bottle making machine is manufactured based upon the strict quality standards for furniture. It has been tested for appearance, physical and chemical properties, environmental performance, weather fastness. It has been granted with the certification of CE. The product contains no harmful substances. It has been clinically proved that all its materials meet international safety standards. The core part of the product is made of high-quality steel, making it high-strength.

We will treat sustainable development in a serious way. We will spare no efforts to reduce waste and carbon footprint during production, and we also recycle packaging materials for reuse.