How about the minimum order value for OEM products?6

Yosion Machinery considers the MOV and MOQ to be similar in some way, so we generally set the MOQ rather than MOV for OEM products. As a large-scale manufacturer, we need to utilize one or several production lines, adopt state-of-the-art technologies, and assign professional employees including senior technicians and skilled workers when we manufacture the OEM products. Throughout the whole process from raw materials purchase to delivery, the manpower and materials inputs are all indispensable. This requires us to set some limits for the OEM orders so as to prevent ourselves from suffering an economic loss.

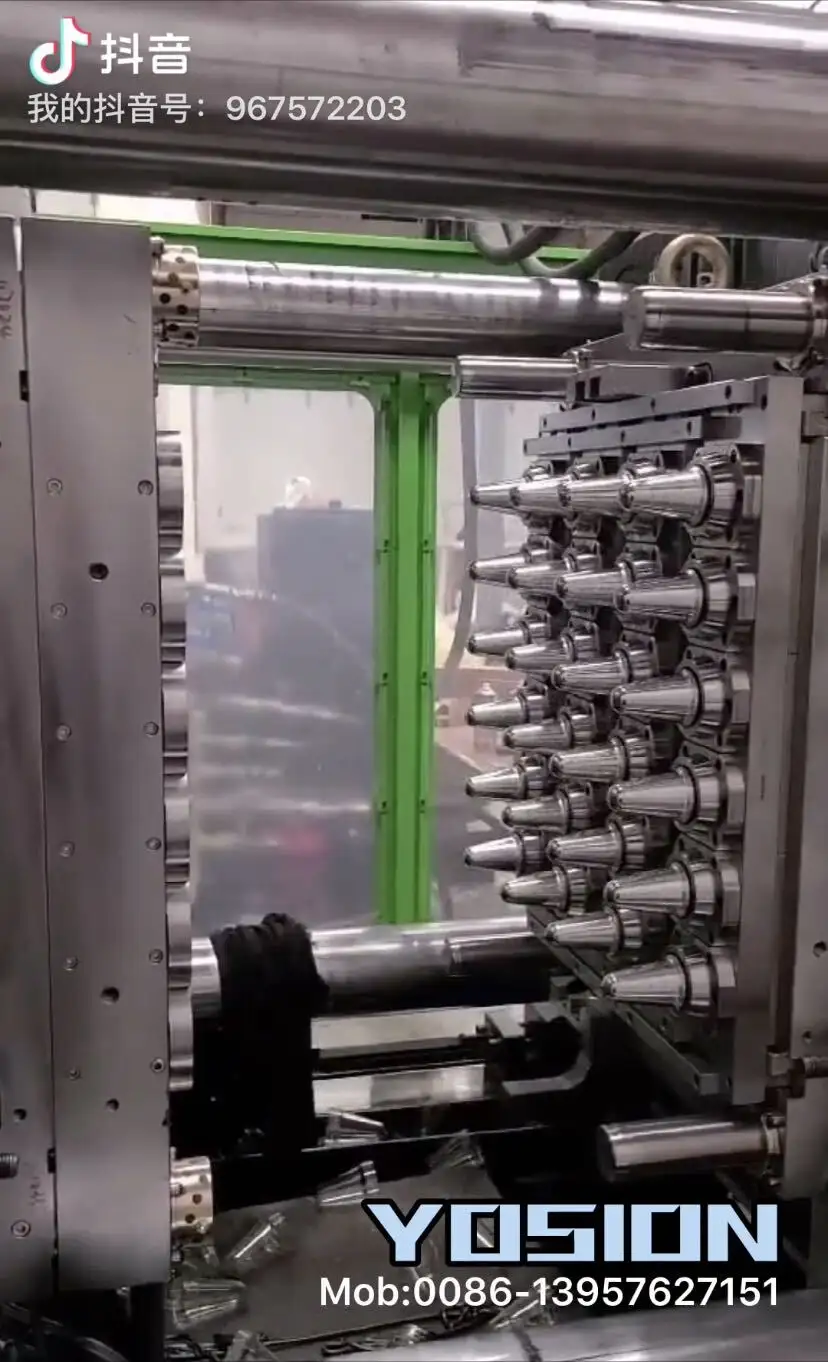

After many years of solid development, Yosion Machinery mainly focus on R&D, designing, producing, and marketing of pet bottle blow molding machine. The manual pet blowing machine series has many styles to meet the diversified needs of customers. Yosion Machinery manual bottle blowing machine is of flexible design. It can be designed for front or back projection, the more common being front projection systems, which have the image source situated on the same side of the screen as the audience. Its independent temperature control device ensures the best preform heating effect. Yosion Machinery has a large showroom and a quality testing laboratory. It is equipped with an advanced cooling system, which will improve work efficiency.

our team highly values the importance of customer satisfication. Check it!